Quality China Clay is the only thing that stands between you and a smooth production process that delivers consistent product quality.

However, you might be struggling to find the right supplier located in the right place that can ensure a steady supply of the Kaolin Clay grade you need.

In fact, I’ve seen many businesses facing challenges in sourcing high-quality China Clay: consistent supply, competitive pricing, and verified quality are major hurdles they often encounter.

If you’re facing this same problem, I’m glad you’re here. In this blog, I’m going to walk you through a step-by-step process on how to find a reliable China Clay manufacturer in India.

I’ll also tell you how to evaluate China Clay samples, what to look for in Kaolin clay manufacturers, and how to choose the best one.

Let’s simplify your procurement journey!

- What is Kaolin (China) Clay?

- Key Applications of Kaolin (China) Clay

- How to Buy Kaolin Clay in Bulk from China Clay Manufacturers in India?

- How to Choose the Right China Clay Manufacturer in India?

- The Sharad Group: Delivering the China Clay You Deserve

- How to Buy Kaolin Clay from Bulk Manufacturers: FAQs

What is Kaolin (China) Clay?

Kaolin clay, popularly called “China clay,” is a soft, white mineral mined from Kaolinite-rich mineral rocks.

Its name comes from “Kao-ling,” a hill in China where it was first extracted for porcelain production centuries ago.

Kaolin Clay’s chemical formula is (Al₂Si₂O₅(OH)₄). Here’s what it means:

Rocks like feldspar contain Kaolinite. Over millions of years, wind, heat, and rain break down these tough rocks, creating pure clay deposits.

And this is what we mine as Kaolin Clay, containing a mixture of aluminium, silicon, and oxygen.

Critical Kaolin Clay Properties for Bulk Purchasers

As one of the leading Kaolin clay suppliers in India, we have noticed a huge increase in demand from clients who want to buy China Clay in bulk. Let me show you why this is the case:

- Purity: Kaolin clay has a relatively simple chemical composition, so it’s one of the most reliable bulk raw materials you can use for manufacturing paper, paints, pottery, and other industrial products.

- Versatility: Kaolin’s clay’s heat resistance and smoothness make it one of the most versatile manufacturing raw materials with a diverse range of industrial applications.

- Consistency: Since Kaolin clay has formed over millions of years, bulk Kaolin Clay manufacturers can deliver consistent quality of raw materials, batch after batch and year after year.

Next, let me show you how & why different industries use Kaolin clay, and how you, too, can use them for your operations.

Key Applications of Kaolin (China) Clay

What's on this page:

Toggle1. Paper Industry

The paper industry is one of Kaolin Clay’s biggest consumers, using it as the primary coating pigment for paper surfaces. In fact, kaolin-coated paper performs better than non-coated paper in terms of both print quality and aesthetic appeal.

When used in bulk, Kaolin Clay helps speed up the printing process by giving the paper a smooth finish. It also reduces the amount of pulp required for paper production by filling up to 30% of the paper volume.

2. Ceramics & Porcelain

Kaolin clay is perhaps most famous for its applications in the ceramics & porcelain industries. That’s because it has a high fusion temperature (1,800°F) and plasticity.

This has made it critical and indispensable for toilets and sinks that require uniform shrinkage and crack resistance! Plus, they’re also very useful for tile production, which accounts for 50-60% of ceramic products.

Operating out of Gujarat’s Morbi, we have consistently supplied thousands of tons of quality Kaolin in bulk to the ceramics industry!

Also Read: How Kaolin Clay Revolutionizes Ceramic Tile Manufacturing?

3. Paints & Coatings

Kaolin also serves as a low-cost extender in paints by taking up 20-30% of its volume. It is a cheaper replacement for titanium dioxide, and can save you up to 20% in pigment costs alone!

Plus, it improves the suspension capabilities and reduces the settling while in storage. Latest studies suggest that the global paints industry will use 2.8 billion tons of Kaolin (China) Clay by 2030!

4. Rubber Manufacturing

Kaolin Clay’s plate-like particles play a critical role in reducing filler costs (up to 50%!) in rubber products. They can also greatly enhance tire tread durability.

So, if you’re producing tires or other rubber products, using Kaolin Clay in bulk can be one of the best investments you can make in your manufacturing process!

Also Read: The Role of Kaolin Clay in the Rubber Industry.

5. Plastics & Polymers

Plastics and polymers are widely used in the food packaging and automotive industries. That means they need a raw material that’s not toxic and durable.

Kaolin (China) Clay ticks both these boxes and offers thermal stability under temperatures of up to 600°C. Plus, it meets FDA-approved standards for non-toxicity, making it a very good option for the food and beverage industry!

In addition to these industries, Kaolin (China) Clay is also used in the cosmetics, construction, pharmaceuticals, glass, and agricultural industries.

How to Buy Kaolin Clay in Bulk from China Clay Manufacturers in India?

In this section, I’m going to walk you through a step-by-step process you can use to buy Kaolin (China) Clay from manufacturers in India.

Here is the exact process that we at The Sharad Group and our clients have used to negotiate bulk China Clay contracts over the past 60 years:

Step 1: Define Your Requirements

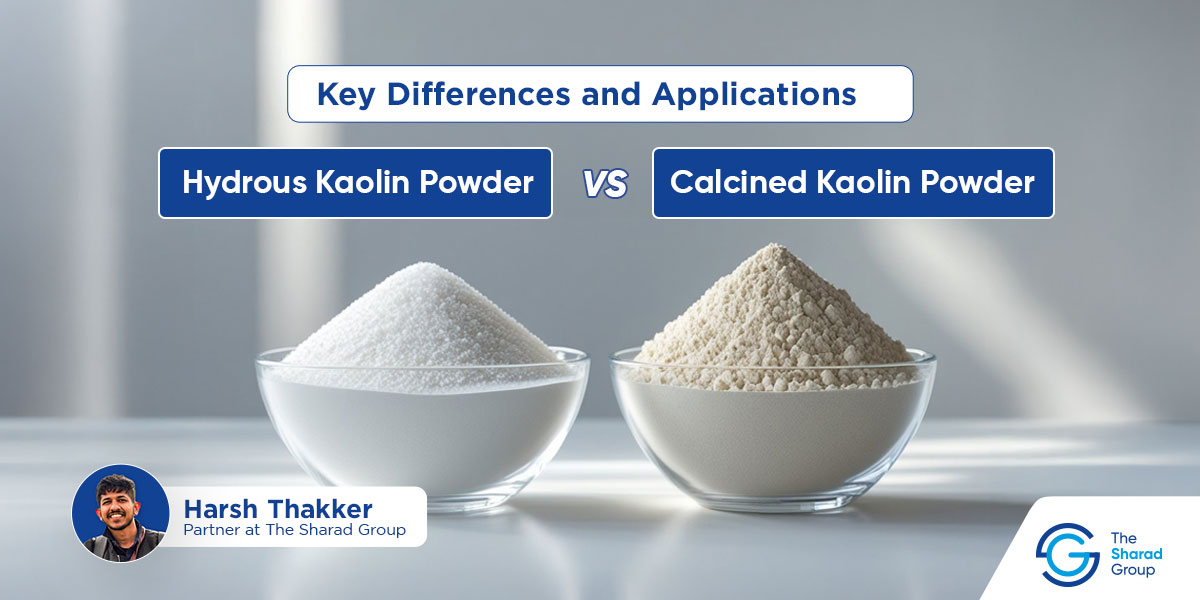

First, you should specify the grade and type of China Clay you need.

For example, you can go for hydrous China Clay if you’re operating in the ceramics or paper industries.

Or, you can get Calcined China Clay if you’re planning to use it as a raw material in paint or rubber manufacturing.

Next, determine the quality parameters your China Clay supply must meet. You can specify parameters like brightness (very important for paper and ceramics) or particle size (for paint manufacturing).

Plus, you can also tell your bulk China Clay manufacturer a particular chemical composition you need, such as low-iron Fe₂O₃ for cosmetics applications.

Lastly, estimate the annual or monthly quantity of China Clay you need. This will help you ask your provider for precise samples or quotes!

Step 2: Research Reputable Manufacturers

Once you know the kind and quantity of the Kaolin (China) Clay you need, you can start searching for reputable bulk manufacturers.

Here’s how you can tell if a China Clay manufacturer in India is reputable:

- Certifications: They will have the necessary certifications, like ISO 9001, BIS, or industry-specific approvals.

- Production Capacity: A good China Clay manufacturer should easily supply at least 500+ MT/month.

- Location: The best China Clay manufacturers in India are located in and around key mines, such as in Kutch (Gujarat), Rajasthan, and Kerala.

Make a checklist of these qualities, and shortlist those Kaolin Clay manufacturers that tick all the boxes.

Step 3: Request Samples & Test Reports

Once you’ve got a list of the best China Clay manufacturers in India, send them requests for samples and quotes.

Ensure that they only send you lab-tested samples, and once you receive them, run your own tests. Here are some parameters you should test for:

- Brightness: Should be above 90% on the Hunter Scale

- Viscosity: 300 to 1,200 cP depending on your application.

- pH level: ideally, it should be between 6 to 8.5.

- Impurity Levels: SiO₂ content should be less than 48% and Al₂O₃ less than 37%.

In our experience, the best way to select a Kaolin Clay supplier is to test samples from 3-5 suppliers. This will give you an idea of the industry benchmark and tell you which China Clay aligns with your raw materials requirements.

Step 4: Negotiate Pricing & Terms

Once you’ve finalized a supplier that meets your quality and quantity requirements, it’s time to negotiate the pricing and terms.

Here are some things you should keep in mind while negotiating:

- Bulk Discounts: You can easily get 10–20% discounts on orders of more than 100 MT/month.

- Payment Terms: Try to negotiate 30-60-day credit periods or LC options. This will help you evaluate the clay once you receive it before making the final payment.

- Hidden Costs: Make sure that you clarify the packaging options (25kg bags vs. bulk shipments), taxes (GST), and port charges before signing the contract.

We also recommend going to your supplier’s factory for an inspection so you can be sure that they have the operations to back up your order.

Step 5: Build Long-Term Relationships

Once you’ve got the Kaoli Clay in your hands, you should also share performance data (like defect rates) to build a long-term relationship with your supplier.

Plus, you can work with your China Clay manufacturer to develop custom grades with special qualities like increased brightness or low abrasion resistance.

How to Choose the Right China Clay Manufacturer in India?

To choose the right China Clay manufacturer in India, you should look for four major things:

1. Quality Checks

The best China Clay suppliers will always conduct and share quality assessment data with you without you even asking them.

They’ll specify the chemical composition, brightness, and particle size, along with other particulars that align with your industrial requirements.

For example, we at The Sharad Group always share our QA process and results with our clients for every order they place!

2. Certifications

Certifications tell you that the China Clay manufacturer has the necessary expertise and licenses to mine, refine, and supply Kaolin clay that’s fit for industrial usage.

In particular, you should look for ISO 9001 and BIS certifications. If you’re going to use Kaolin Clay in the food and beverage industry, you should also ensure that your supplier is offering food-grade Kaolin (China) Clay.

3. Logistics

The best China Clay suppliers don’t just offer quality raw materials; they’re also located near key ports to reduce the cost of doing business.

That means they should have supply chains around major ports like Kandla or Mundra, or offer complete logistics support from port to warehouse for your Kaolin Clay.

We speak from experience: in the 60+ years that we’ve been supplying Kaolin Clay, we’ve developed robust supply chains that span from mines in Gujarat to markets around the world.

4. Experience

Your Kaolin Clay supplier’s experience doesn’t just tell you that they’re good at mining and refining China clay.

It means they’ve weathered the storm over decades and gone through periods of booms and busts. It shows that they are backed by structures and operations that assure steady production and supply!

So, try to work with an experienced China Clay manufacturer in India for consistent, quality raw material supply for your operations.

The Sharad Group: Delivering the China Clay You Deserve

In this blog, I’ve walked you through a step-by-step process on how to source quality Kaolin Clay from an Indian manufacturer.

And if you’re looking for a steady supplier with years of experience and a solid supply chain, why not connect with us at The Sharad Group?

We have been a trusted name among China Clay manufacturers in India for over 60+ years, supplying premium-grade kaolin to 500+ global clients.

With strategically located mines in Gujarat, state-of-the-art processing units, and a robust supply chain near key ports, we ensure consistent quality, bulk reliability, and competitive pricing.

Ask us for a free sample and quote, and experience seamless bulk procurement backed by decades of expertise.

Plus, if you’re not sure what type, grade, or chemical composition you should specify, get in touch with us!

We’ll help you find the right China Clay grade that aligns with your purpose and delivers quality results, every single time…

How to Buy Kaolin Clay from Bulk Manufacturers: FAQs

1. How do I verify a reliable China clay manufacturer in India?

Check for ISO 9001/BIS certifications, production capacity (500+ MT/month), and proximity to mining hubs like Gujarat or Rajasthan.

2. What’s the typical price range for wholesale kaolin clay?

₹1,500–₹30,000/MT, depending on grade (hydrous/calcined) and order volume (bulk discounts apply for 100+ MT).

3. Which industries use kaolin clay the most?

Paper (40% global demand), ceramics, paints, rubber, and plastics industries are the biggest users of Kaolin (China) Clay due to its brightness, heat resistance, and cost efficiency.

4. What quality tests should I run before bulk purchase?

Test brightness (>90% Hunter Scale), viscosity (300–1,200 cP), pH (6–8.5), and impurities (SiO₂ <48%, Al₂O₃ >37%).

5. Why choose Indian kaolin clay manufacturers?

India’s mineral-rich regions (e.g., Kutch) offer high-grade clay, competitive pricing, and robust logistics near key ports like Mundra. This will help you save on transportation costs while ensuring a steady supply of quality Kaolin (China) Clay.